FAQ - Check Valves

More about Check Valves

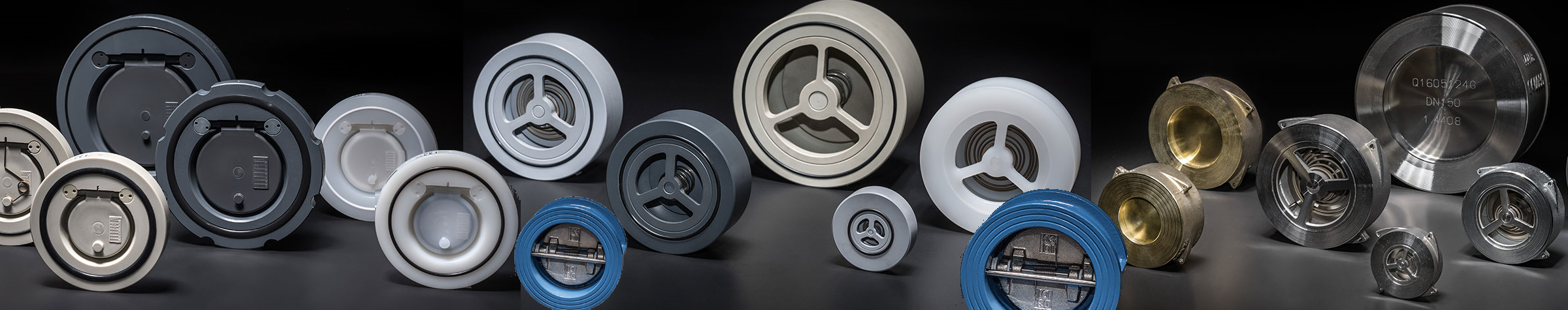

Check valves in intermediate flange design with a shut-off element made of one piece or as a check valve with double wings - metal or elastic sealing. Low pressure drop and low opening pressure. The check valve is installed between flanges according to DIN/ANSI in horizontal or vertical piping systems. Our range includes a complete catalog of check valves made of different materials such as stainless steel, galvanized steel, plastic, aluminum, aluminum bronze, etc. We have the usual materials NBR, EPDM, FPM (Viton), and PTFE to choose from as seals, and a metal seal is also possible. Disc check valves are particularly suitable for industrial use in piping systems for the transport of liquid and gaseous substances.

Types of Check Valves

- Inline check valve

- Intermediate flange check valve

- Double-wing check valve

- Check valve

- Ball check valve

- Disc check valve

The choice of the check valve type depends on the application, medium, pressure, temperature, and installation possibilities. Ebora can assist you in choosing the right check valve for your application.

Intermediate Flange Check Valve

The intermediate flange check valves are fittings (valves) designed to prevent backflow in piping systems. These check valves are characterized by their simple construction and short installation lengths. They are designed for direct mounting between DIN flanges (intermediate flange check valve). The check valves of the EBZRK-EBZRKF series are suitable for industrial use in piping systems for the transport of liquids and gaseous substances of group 1 (explosive, flammable, toxic, combustible) and 2 (all others) according to the Pressure Equipment Directive 97/23/EC. They are not suitable for solids. Due to the adapted outer diameter of the housing, the check valve is centered between the screws of the flanges during installation. The check valve is externally sealed with a gasket. Therefore, we recommend using flange bushings with smooth sealing surfaces. These check valves have a low opening pressure. The resulting opening force bends the disc against the spring (EBZRKF) and the weight of the disc so that the medium is released. To achieve possibly higher flow rates, we can allow a larger opening angle of the disc upon request. If the outlet pressure exceeds the inlet pressure, the valve closes and seals against the medium via the O-ring. The intermediate flange check valves are maintenance-free.

Disc Check Valve

Our disc check valves are characterized by their simple construction and short lengths (according to DIN EN 558-1, series 49). They offer an optimal solution for larger nominal widths and wherever intermediate flange connections are required or more cost-effective. The check valves of the EB930 series are suitable for industrial use in piping systems for the transport of liquid and gaseous substances, as well as in systems where particularly high demands are placed on the material. The installation position is optional with disc check valves. They are opened by the pressure of the medium and closed by a spring when the flow is reduced before backflow occurs.

Double-Wing Check Valve

The double-wing check valves of the EB915 series are characterized by their simple construction and short lengths (according to DIN EN 558-1, row 16). They can be directly mounted between DIN flanges (PN 10, PN 16). Our double-wing check valve has a low opening pressure. The resulting opening force bends the wing against a spring and the weight of the wing so that the medium is released. If the outlet pressure exceeds the inlet pressure, the check valve closes and seals against the medium via the O-ring. These double-wing check valves are maintenance-free.

Materials of Check Valves

Applications of Check Valves

- Water/Wastewater Technology

- Heating/Air Conditioning/Sanitary

- Building Technology

- Chemical Industry

- Plant Engineering

Why Choose Ebora's Check Valves:

- The factory has its own test benches for pressure and leak tests

- Assembly, final inspection, and acceptance by qualified specialists

- Delivery with factory certificates according to DIN EN 10204 2.2 and Acceptance Test Certificates according to DIN EN 10204 3.1 possible

- CE marking including declaration of conformity possible

- Operational processes according to the established QM manual based on the ISO 9000 ff series

If you are a bulk buyer, Ebora is your check valves supplier.

Ask about our OEM bulk packages with matching prices.