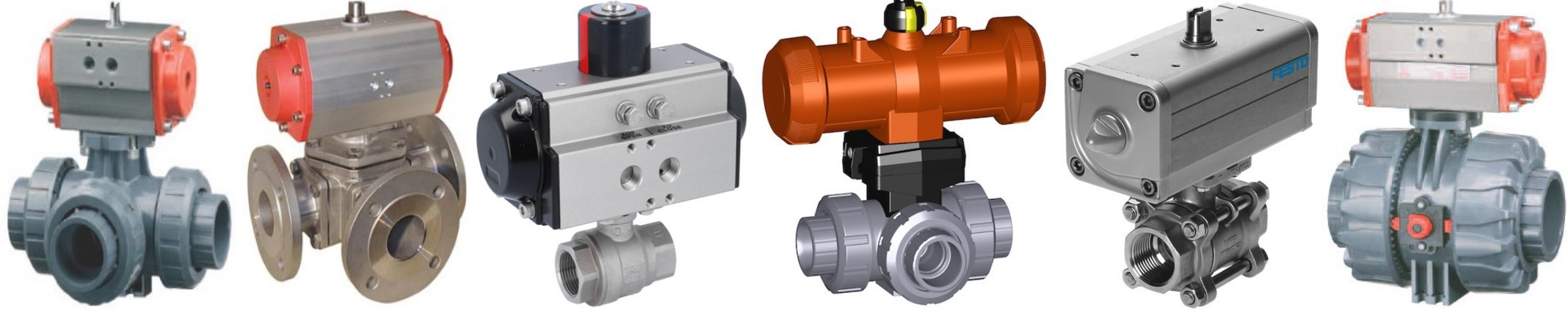

This is the subpage for pneumatically actuated ball valves. For manually operated, electrically actuated or free-stem ball valves, please see the dedicated pages.

What is a pneumatically actuated ball valve?

An actuator converts compressed air into rotation. The ball turns exactly ninety degrees.

In the open position, the bore is aligned with the pipeline and the medium can flow.

In the closed position, the bore is perpendicular to the pipeline and the valve seals completely.

The simple quarter-turn operation yields minimal pressure drop and consistent performance.

Design, interfaces and materials

The actuator and valve are coupled via an ISO 5211 mounting flange.

The drive shaft must match; otherwise we fit a suitable adapter or bracket.

NAMUR/VDI-VDE 3845 simplifies the mounting of solenoid valves and limit switches.

Ball valves are available in steel, brass and stainless steel for corrosion resistance.

Seats are selected for wear, chemical resistance and temperature; PTFE is often the baseline.

End connections include threaded, welded or flanged in DIN or ANSI. The choice follows the process.

Plastic variants such as PVC and PP are also feasible within appropriate pressure and temperature ranges.

Actuator types and fail-safe behaviour

Select the drive based on safety and system requirements, and define the required stroke.

- Single-acting: spring return for fail-close or fail-open upon air loss.

- Double-acting: compressed air for opening and closing, compact and fast.

Mechanically, there are rack-and-pinion and scotch yoke principles; the torque profile differs.

Rack-and-pinion delivers a uniform torque; scotch yoke peaks at breakaway.

Selection and sizing

Start with the medium. Is it lubricated or dry, and possibly abrasive?

Fix pressure and temperature. Choose materials that meet standards and service life.

Bore follows flow. Determine Kv or Cv and the allowable pressure drop.

Operating torque depends on seat, pressure and medium. Dry media require more torque.

We size with margin on break and seat torque for reliable operation.

Also note the available air supply pressure. Typical values are between five and seven bar.

Match the ISO 5211 flange and the drive shaft interface; add a bracket or adapter if needed.

After assembly we set end stops, position indication and stroke, then perform a functional test.

Why choose pneumatic actuation?

- Fast switching and high reliability, including in humid environments.

- No EMC emission and favourable costs for larger diameters and high cycle rates.

- Modular design makes service and retrofit straightforward and predictable.

- Fail-safe function is relatively simple and low-cost.

The combination of modular design and a robust actuator makes the assembly low-maintenance compared to manual variants.

For some processes, electric actuation is suitable—see our page on electrically actuated options.

Typical applications

Common domains include process water, compressed air and inert gas in industry.

Oil and fuels are also possible with suitable seats and sealing materials.

In (petro)chemicals and tank storage, fail-safe behaviour is often a strict requirement.

Typical sectors are the chemical industry, food & beverage (hygienic design), water treatment and HVAC systems.

Quality, emissions and safety

Our ball valves feature an anti-blowout stem and antistatic provisions are often available.

Where requested, we comply with TA-Luft or ISO 15848. Documentation is available.

Actuators are optionally available with ATEX and SIL documentation for risk studies.

Valve Automation Center

We provide assembly, adjustment and testing in our Valve Automation Center.

You receive test reports and a clean documentation set for traceability on request.

Frequently asked questions about pneumatically actuated ball valves

How does a pneumatic ball valve work?

A pneumatic actuator converts compressed air into a 90-degree rotary motion. This quarter-turn opens or closes the passage through the ball. In the open position, the bore aligns with the pipeline and pressure drop is minimal. In the closed position, the bore is perpendicular to the pipeline and the shut-off is tight within the specified leakage class.

What is the difference between single-acting and double-acting actuators?

A single-acting actuator has a spring return and moves to a safe position (fail-close or fail-open) on air loss. This is ideal for process safety and emergencies. A double-acting actuator uses air for opening and closing and offers a compact package with fast cycle times. The choice depends on the desired fail-safe behaviour, air supply and switching frequency.

Which mechanism does Ebora recommend: scotch yoke or rack-and-pinion, and why?

Ebora generally prefers scotch yoke because of its robust design and high breakaway torque. In our configurations there is typically little to no price premium versus rack-and-pinion, while air consumption per cycle is significantly lower. Using less compressed air usually means lower energy costs and reduced compressor load. We of course supply rack-and-pinion on request or where the application specifically requires it.

How do I determine the required operating torque and actuator size?

Start with the valve manufacturer’s data for break, run and seat torque at your process conditions. Adjust for medium (lubricated or dry), pressure and temperature, and include an adequate safety margin. Match the actuator to the available air pressure so the effective torque is sufficient in all positions. After assembly, set end stops and feedback, and perform a functional test.

Is a pneumatic solution suitable for ATEX or wet environments?

Yes. Pneumatics are widely used in hazardous (ATEX) or wet environments because no electric motor is required on the actuator itself. This avoids EMC emission and reduces ignition sources. Actuators and accessories are available with ATEX options and appropriate enclosures. Ensure proper air conditioning and the correct solenoid valve.

Can I operate a pneumatic ball valve remotely?

Yes—via a (NAMUR) solenoid valve the actuator can be controlled electrically from a distance. A switch box or sensors provide open/close feedback to your PLC or DCS. Integration is straightforward thanks to ISO 5211 mounting and VDI-VDE/NAMUR interfaces. For high reliability, use filtered and regulated compressed air with adequate flow capacity.