Elaflex DE probleemoplossers binnen leidingsystemen:

ELAFLEX HIBY is a family-owned company who has become one of the leading international specialist for refuelling equipment in its corporate history.

The group comprises four sales divisions: Hoses and Couplings (SAT), Rubber Expansion Joints (ERV), Petrol Station Equipment (EHT) and CASTING Products.

Ebora only represents Elaflex for Rubber Expansion Joints (ERV)

ELAFLEX RED BAND expansion joints

for water, drinking water (approval ELL as well as ACS, conform to FDA), cold and warm waste water, seawater, cooling water, also with chemical additives for water treatment, low concentrated acids and alkalis, salt solu - tions, technical alcohols, esters and ketones. Can be used in oily atmospheric environments, e.g. engine rooms. Temperature range (depending on medium) -40°C up to +100°C, temporarily up to +120°C. Electrically dissipative. Not suitable for all kinds of mineral oil products, cooling water with added oil containing corrosion preventatives, oily compressor air. Liner : Butyl (IIR)/EPDM, seamless, low permeation Reinforcement : PA textile cord, Butyl rubberized Cover : EPDM, ozone proof, heat resistant Marking : Red band, ERV DN .., PN .., production date Flanges1) : Swivelling, DIN PN 10/16, carbon steel, zinc plated

ELAFLEX ROTEX expansion joints

for permanent use with hot heating water, cooling water and hot air. Approved according to DIN up to +100°C by 10bar and up to +110°C by 6bar. Temperature range (depending on medium) -40°C up to +130°C, temporarily up to +150°C. Electrically dissipative. Not suitable for drinking water, cooling water with oil containing additives, oily compressor air, permanent effect of steam. Liner : EPDM, hot water resistant, seamless, abrasion resistant Reinforcement : Polymer textile cord, hot water and hydrolysis proof Cover : EPDM, ozone proof, heat resistant Marking : Two red bands, ERV DN .., PN .., production date Flanges 1) : Swivelling, DIN

ELAFLEX CR expansion joints

for cold and warm water, swimming pool water, sea water, waste water (weakly sour or alkaline) also oil containing, cooling water with protective oils against corrosion, lubricating oil, grease and air, compressed air. Temperature range (depending on medium) -25°C up to +90°C, temporarily up to +100°C. Electrically non-conductive. Not suitable for drinking water, acids, alkalis, chemicals, heating oil, diesel, gasoline and jet fuel, petroleum, solvents, other hydrocarbons and hot compressed air. Liner : Chloroprene CR, seamless, abrasion resistant Reinforcement : PA textile cord Cover : Chloroprene CR Marking : White imprint 'CR', ERV DN .., PN .., production date Flanges1) : Swivelling, DIN PN 10/16, carbon steel, zinc plated

ELAFLEX BR Expansion Joints

, special type for abrasive media such as sludges, slurries, solid/liquid mixtures and emulsions, dustlike or powdery products (e.g. carbon-blacks). Also suitable for all kinds of water (non oil containing) as well as various chemicals. Not suitable for petroleum based products. For extreme strain (e.g. sharp and rough-edged matter) we suggest the use of ERV with inner protection sleeve type SR, see page 467. Temperature range (depending on medium) -50°C up to +70°C, temporarily up to +90°C. Electrically dissipative. Liner : BR/NR, seamless, high abrasion resistant Reinforcement : Polyester textile cord Cover : BR/NR Marking : Blue spot, ERV DN .., PN 16, production date Flanges 1) : Swivelling, DIN PN 10/16, carbon steel, zinc plated

ELAFLEX RED SPOT expansion joints

for sanitary installations, cold and warm water, pool water, sea water, drinking water. Highly flexible and low own restistance. Temperature range (depending on medium) -40°C up to +90°C, temporarily up to +120°C. Electrically dissipative. Not suitable for all kinds of mineral oil products, cooling water with added oil containing corrosion preventatives, oily compressor air, for permanent working pressure > 10bar. Liner : Butyl (IIR)/EPDM, seamless Reinforcement : PA textile cord Cover : EPDM Marking : Red spot, ERV DN .., PN 10, production date Flanges 1) : Swivelling, DIN PN 10 carbon steel, zinc plated

ELAFLEX YELLOW BAND expansion joints

suitable for petroleum based products with aromatic content up to 50%, fuels (ethanol content up to 85%), aviation fuels, town gas and natural gas except liquefied petroleum gas. Temperature range (depending on medium) -20°C up to +90°C, temporarily up to +100°C. Electrically dissipative. Liner : NBR (nitrile), seamless, abrasion resistant Reinforcement : PA textile cord Cover : Chloroprene CR Marking : Yellow band, ERV DN .., PN .., production date Flanges 1) : Swivelling, DIN PN 10/16, carbon steel, zinc plated

ELAFLEX YELLOW STEEL expansion joints

for petroleum based products, DIN EN fuels up to 50% aromatic content, cooling water with oily anticorrosion additives, lubrication and hydraulic oil, seawater. Temperature (depending on medium) range -20°C up to +90°C, temporarily up to +100°C. Fire resistant (to ISO 15540) up to 30 min. at 800°C. Electrically dissipative. Liner : NBR (nitrile), seamless, abrasion resistant Reinforcement : Steel wire cord Cover : Chloroprene CR Marking : Two yellow bands, ERV DN .., PN .., production date Flanges 1) : Swivelling, DIN PN 10/16, carbon steel, zinc plated

ELAFLEX YELLOW STEEL HNBR expansion joints

for petroleum based products, DIN EN fuels up to 50% aromatic content, cooling water with oily anticorrosion additives, lubrication and hydraulic oil, seawater. Very good aging, weathering and ozone resistance. Temperature (depending on medium) range -35°C up to +100°C, temporarily up to +120°C. Fire resistant to ISO 15540 up to 30 min. at 800°C. Electrically dissipative. Liner : HNBR (nitrile), seamless, high abrasion resistant Reinforcement : Steel wire cord Cover : Chloroprene CR Marking : Yellow-blue-yellow bands, ERV DN .., PN .., production date Flanges1) : Swivelling, DIN PN 10/16, carbon steel, zinc plated

ELAFLEX YELLOW BAND LT expansion joints

designed for low temperature applications for standard-conform petroleum based products, e.g. diesel, heating oil up to +90°C, aviation fuels, petroleum up to +60°C and gasoline up to +40°C. Temperature range (depending on medium) -40°C up to +90°C, temporarily up to +100°C. Electrically dissipative. Liner : NBR (nitrile), seamless, abrasion resistant Reinforcement : PA textile cord Cover : Chloroprene CR Marking : Yellow band with white 'LT' print, ERV DN.., : PN 16, production date Flanges 1) : Swivelling, DIN PN 10/16, carbon steel, : zinc plated

ELAFLEX YELLOW BAND expansion joints

suitable for petroleum based products with aromatic content up to 50%, fuels (ethanol content up to 85%), aviation fuels, town gas and natural gas except liquefied petroleum gas. Temperature range (depending on medium) -20°C up to +90°C, temporarily up to +100°C. Electrically dissipative. Liner : NBR (nitrile), seamless, abrasion resistant Reinforcement : PA textile cord Cover : Chloroprene CR Marking : Yellow band, ERV DN .., PN .., production date Flanges 1) : Swivelling, DIN PN 10/16, carbon steel, zinc plated

ELAFLEX ORANGE BAND expansion joints

for Liquid Petroleum Gas (LPG) to EN 589. For tank trucks and refuelling stations. Temperature range (depending on medium) -20°C up to +90°C, temporarily up to +100°C. Electrically dissipative. Liner : NBR (nitrile), seamless, abrasion resistant Reinforcement : PA textile cord Cover : Chloroprene CR Marking : Orange band, ERV DN .., PN 25, : production date Flanges 1) : Swivelling, DIN 2635/PN 40 carbon steel, : zinc plated

ELAFLEX GREEN BAND expansion joints

for chemicals, acids, alkalis and aggressive chemical waste water. For oil-contaminated compressed air up to +90°C. Temperature range (depending on medium) -20°C up to +100°C, temporarily up to +110°C. Electrically non-conductive. Liner : CSM, seamless, abrasion resistant Reinforcement : PA textile cord Cover : CSM Marking : Green band, ERV DN .., PN .., production date Flanges1) : Swivelling, PN 10/16, carbon steel, zinc plated

ELAFLEX WHITE BAND expansion joints

for foodstuffs, also containing oil and fat. Liner corresponds to Recommendation XXI of BfR and FDA-21CFR 177.2600. Not approved for drinking water. Temperature range (depending on medium) -20°C up to +90°C, temporarily up to +100°C. Electrically non-conductive. Liner : NBR light grey, seamless, abrasion resistant Reinforcement : PA textile cord Cover : Chloroprene (CR) Marking : White band, ERV DN .., PN .., production date Flanges 1) : Swivelling, PN 10/16, carbon steel, zinc plated

FLANGE CHOICE

For the choice of flanges a great variety of combinations concerning connection dimensions, materials and coatings is available. Also two different flange types on one compensator are possible. On the following pages the most common types and dimensions are listed. Special types are available upon request.

ELAFLEX ERV Tie Rods and Angular Limiters

Tied Flanges – Type ZS The table shows that the pressure thrust forces in small ERV dimensions up to DN 50 are this low that limiters normally are not necessary. Limiters are recommended when it is not possible to secure the pipe system with sufficient fixed points or when a part relief of the fixed points is desired. The required limiters are measured to absorb also the reaction forces resulting from the test pressure. For the mainly required axial limitation the shown types with integrated tie bars have proved well. The tie bars with high stability (steel 8.8) can be adjusted to the actual installation measurements. The tie bars lie elastically in noise reducing rubber bushes of weatherproof rubber. From DN 350 the tie rods lie in prinicipal in conical seats and spherical washers. When assembling ERV ZS / ZSS ensure that the nuts on the threaded rods are fixed with locking nuts. Please observe the Maximum admissible ( L max ) elongation of the bellows stated on our catalogue.

ELAFLEX Type SR

ERV with inner protection sleeve SR of stainless steel AISI 316 Ti to prevent abrasion of the rubber liner, i.e. for mediacontaining abrasive components or to avoid cavitation. Please note: The nominal bore is reduced.

ELAFLEX Type TA / TA OHM

ERV with white PTFE lining TA. Electrically isolating, therefore not suitable for flammable liquids in Ex-Zones. ERV with black, conductive PTFE lining TA OHM. Suitable for flammable liquids in Ex-Zones (on request).

ELAFLEX Type TAS / TAS OHM

ERV with white PTFE lining and PTFE vacuum support ring TAS. Properties like type TA, but also suitable for vacuum service, up to 70°C. ERV with black, conductive PTFE lining and PTFE vacuum support ring TAS OHM. Properties like type TA OHM, but also suitable for vacuum service, up to 70°C.

ELAFLEX Type VSD

ERV with vacuum support spiral. Spiral of AISI 316 Ti, used when the vacuum resistance * of the chosen ERV is not sufficient.

ELAFLEX Type VSR

ERV with vacuum support ring. Ring of AISI 316 Ti, used when the vacuum resistance * of the chosen ERV is not sufficient.

ELAFLEX Type VSRV

ERV with bolted vacuum support ring. For maximal vacuum resistance * of the selected ERV. Bolted ring in stainless steel AISI 316 Ti.

ELAFLEX Type FSH

Flame protection cover for ERV rubber expansion joints, made of several layers of glass fiber fabric with a surface cover of silvercoloured high temperature resistant silicone-aluminium-glas fabric (certified acc. MED A1/3.13). Screws, nuts and washers of brass. It reliably protects the expansion joint against radiation heat and direct flames up to 800° C for 30 min. (ISO 15540). Flame protection covers are resistant against oil and chemical influences as well as against ageing and weathering. Due to its split design the flame protection cover can be mounted subsequently and re-opened. Dimensions are chosen in a way that also the counter flanges are completely covered. The allowed range of movement is not restricted.

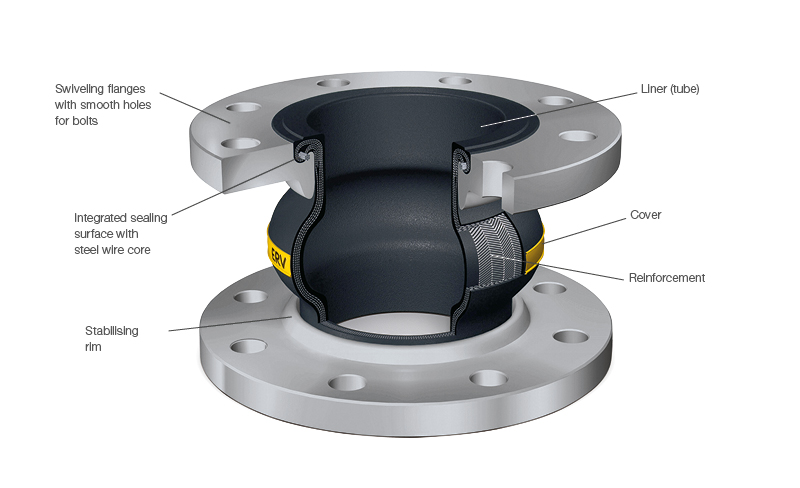

Manual for the Pipework Designer ERV rubber expansion joints are delivered ready for installation. The swivelling flanges can be fitted in any desired position and have stabilising rims to ease the assembly. Flanges with stabilising rim (collar) also help to maintain a safety gap between screw ends and the bellows throughout the whole range of movement and avoid injuries. Correct Mating Flanges (Figures A–G) Gaskets are not required if the sealing surface of the pipework mating flanges are designed as shown on the right hand side. Gaskets should only be used in order to prevent damage to the rubber sealing surface, for example if the mating flanges show sharp inner edges or irregularities e.g. welding beads. If the internal diameter of the mating flanges is too large (sealing surface of the expansion joint not fully covered), install a gasket and an additional disc (fig. E). Pressure Resistance The maximum operating pressure and test pressure not only depend on the burst pressure of the rubber bellow but can also be affected by operating temperature and design pressure/nominal pressure of the used flanges. For full details please see catalogue page 404. The burst pressure (at room temperature) is at least 3–4 times the nominal pressure (PN). Pressure test certificates can be issued upon request. Vacuum Resistance The maximum vacuum depends on size, operating temperature, length of installation and the installation of vacuum support rings (page 468). Please see type specific data sheets for details. The vacuum resistance can be slightly increased even without vacuum support rings if the installation length is shortened (e.g. by 20mm). The vacuum resistance decreases if a longer installation length is chosen, or the expansion joint is lengthened during operation. Weather and Heat Resistance The outer rubber (cover) is resistant against weathering and protects the reinforcements against ageing, abrasion and corrosion. For the permitted temperature range please see type specific data sheets. For permanently warm operating conditions including external radiation heat please see page 404. ERV types with an outer rubber of CR or CSM are (within limits) oil proof and flame resistant. An additional flame protection can be achieved by using our flame protection cover conforming to ISO 15540 standard (certificate 'DNV·GL') – see catalogue pages 471 and 472. Pressure Loss The internal design of the ERV bellows allows a high flow with little turbulence. Therefore the pressure loss is usually negligible, even when dealing with high flowrates. Maximum Flow Velocity Flow velocity should not exceed 7m/s. For flammable fluids, the maximum flow velocity should be further reduced depending on the electrical conductivity of the fluid. For non conductive and flammable fluids such as toluene a value of 2m/s should not be exceeded. Noise Reduction Due to their construction, ERV rubber expansion expansion joints are well suited to absorb vibrations and noise. An ERV installed within a piping system achieves a partial decoupling of vibration and noise transmission. The degree of this effect is dependent on the layout of the piping system and the assembly situation of the expansion joint. The pipework and the installed expansion joint may be seen as spring-mass system; its natural frequency is determined by the spring rigidity as well as by the oscillating mass. In comparison to the piping system, the mass of an ERV has a neglectable influence on the natural frequency of the piping system. Installation Length / Installation Gap For the allowable range of movement please see type specific data sheets. If possible, the length of the installation gap is designed to be equal to the recommended installation length, or slightly shorter. The low inherent resistance of ERV makes fitting into smaller gaps easy. For larger installation gaps or lateral offset, not more than 50% of the maximum area of movement should be used up in order to leave a reserve for operation. If the bellows is lengthened during operation, a jolted (compressed) installation is recommended. The position of installation must be accessible for visual inspection. When installing the unit, installation hints (catalogue page 479) must be observed. Anchor Load / Tie Rods (Limiters) The inherent resistance of an ERV is small and can be disregarded for anchor force calculation. But when pressurised, the bellows expands and generates an axial force. Therefore, especially for larger expansion joints, fixed points (anchors) should be provided. Since the ERV construction absorbs part of these reaction forces, anchor points may be designed correspondingly weaker. If anchor points cannot be provided, or if the stability of the piping system or other fittings is insufficient, reaction forces have to limited by tie rods – available types see catalogue catalogue page 464. Important Note: Allowable Range of Movement The range of movement listed in the tables on reverse side of our ERV catalogue pages are to be understood as only axial or lateral or angular range of movement. For combined movements (e.g. axial and lateral) the percentual value is only allowed to add up to a maximum of 100%. In case an over all sum of > 100% is needed please ask our sales. Example: (table on page 408) ERV-R BL 130 DN 150 – e. g. max. axial movement of 50% and max. lateral movement of 50%: Allowed axial range of movement Lmin. = 115mm (BL minus 50% of the difference between BL and Lmin), Lmax. = 140mm (BL plus 50% of the difference between BL an Lmax) and allowed lateral range of movment l = +/- 15mm (50% of l).